Table of Contents

- Introduction

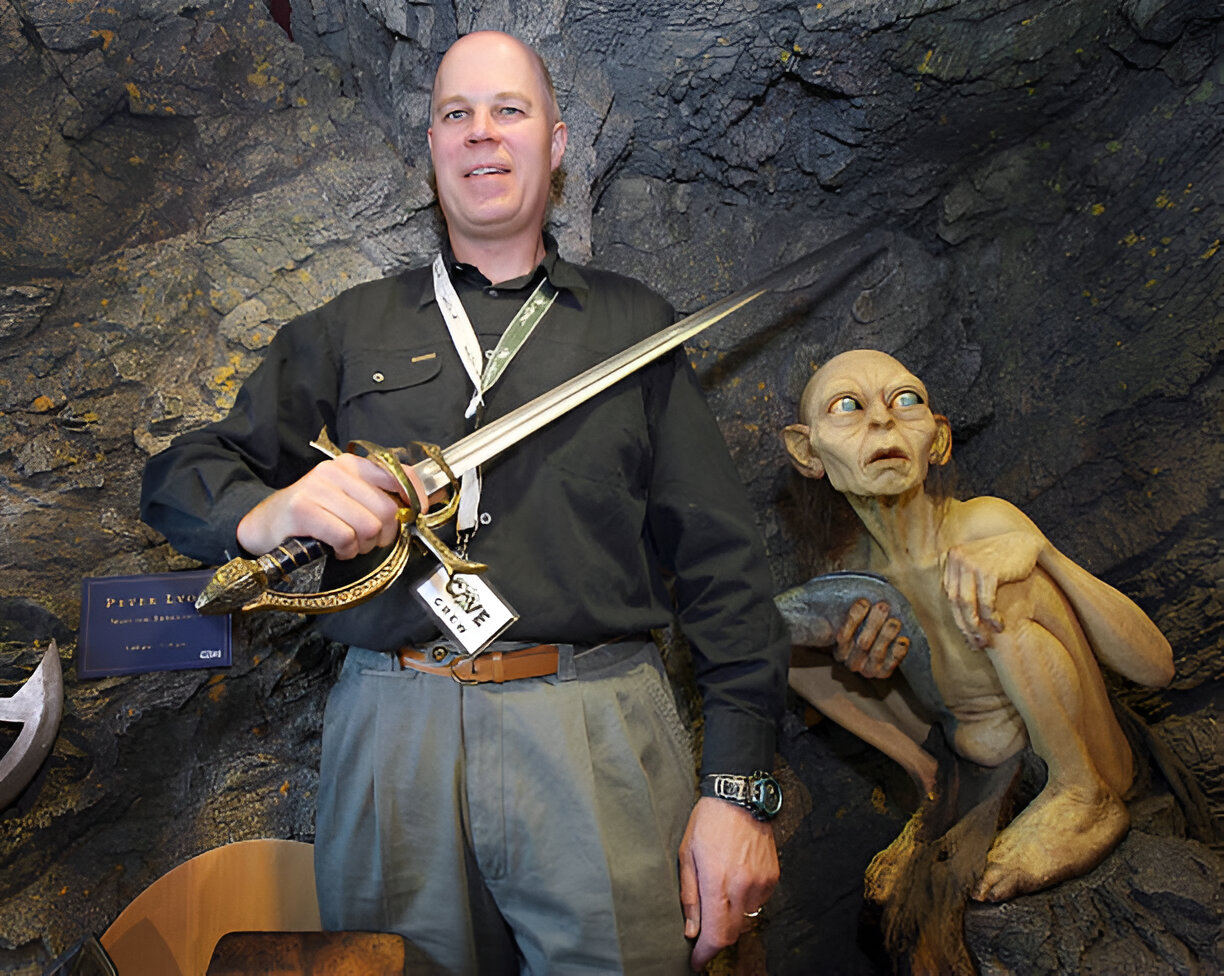

- Spotlight on Peter Lyon

-

Interview

- 1. From self-taught swordsmith to film industry legend

- 2. The most challenging weapon to create

- 3. The design and symbolism of Andúril

- 4. The inspiration behind Orcrist’s unique design

- 5. Crafting 4,000 weapons for “Mulan”

- 6. The impact of modern technology on swordsmithing

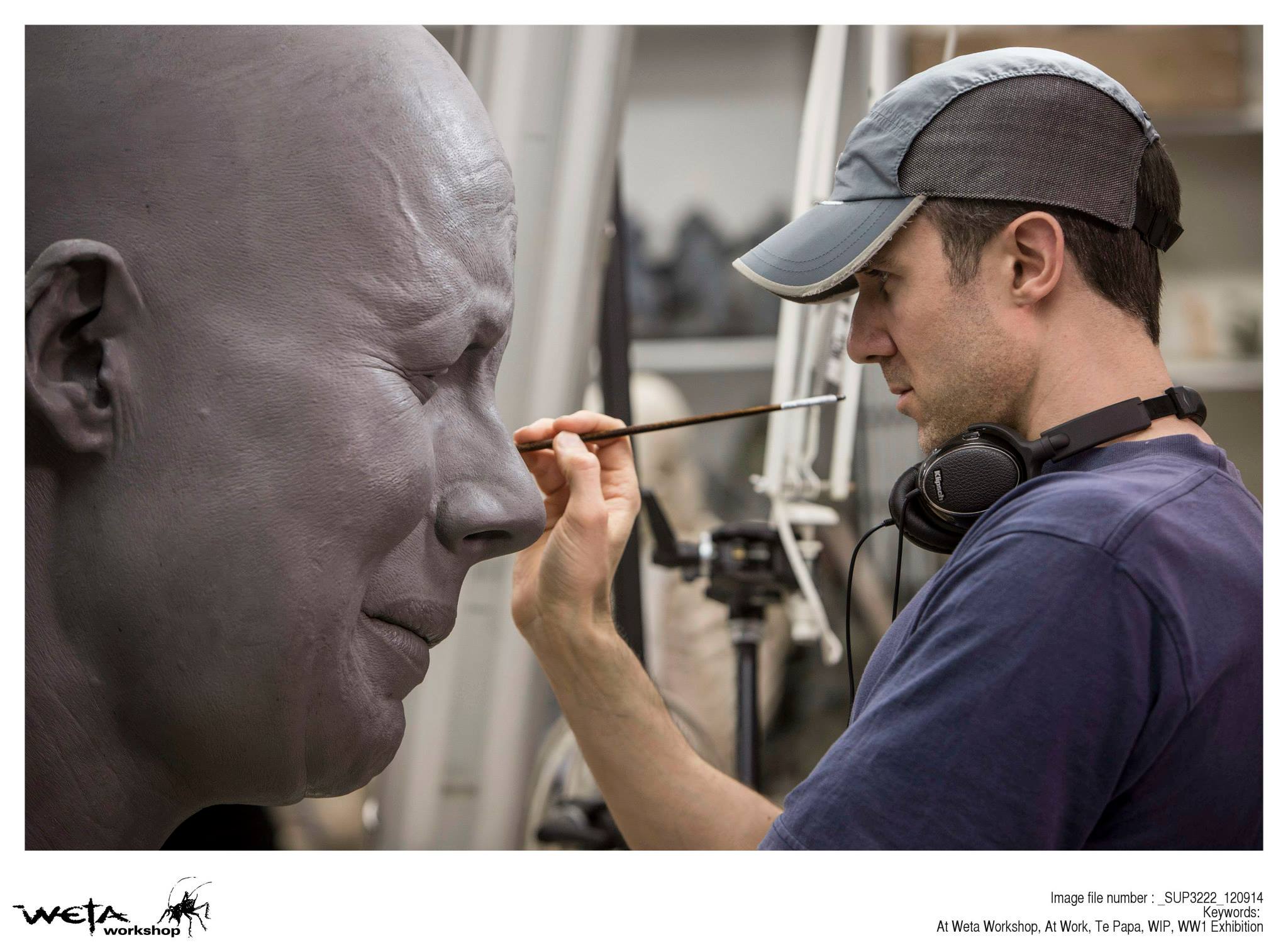

- 7. The power of teamwork at Wētā Workshop

- 8. Balancing realism, safety, and functionality in film props

- 9. Seeing your work become part of pop culture

- 10. Adapting screen-used props into collectibles

- 11. The future of traditional prop-making in a digital world

- 12. Advice for aspiring swordsmiths and prop makers

Introduction

In February 2025, we had the honor of conducting an exclusive interview with Peter Lyon, the master swordsmith behind Wētā Workshop’s most iconic weapons. Known for his exceptional craftsmanship in films like “The Lord of the Rings” and “The Hobbit” trilogies, Peter shared insights into his journey, the art of sword-making, and his experiences in the film industry.

Spotlight on Peter Lyon

Peter Lyon is a world-renowned swordsmith from New Zealand, best known for his work at Wētā Workshop, where he has crafted legendary weapons for films such as The Lord of the Rings, The Hobbit, and Mulan. His exceptional craftsmanship has brought to life some of the most iconic blades in cinematic history, including Andúril, Orcrist, and Sting.

From Hobbyist to Master Swordsmith

Born and raised in Shannon, New Zealand, Peter began his journey as a self-taught swordsmith. His passion for historical European weaponry led him to experiment with blade-making techniques, refining his skills through trial and error. His meticulous attention to detail caught the eye of Wētā Workshop, where he was invited to work on The Lord of the Rings trilogy, marking the beginning of an extraordinary career.

Crafting Weapons for Hollywood

Peter’s expertise extends beyond aesthetics—his swords are designed with both authenticity and functionality in mind. His work on The Lord of the Rings and The Hobbit required him to create weapons that not only looked historically and culturally accurate but could also withstand the rigors of filming intense battle sequences. He later expanded his contributions to films like Mulan, where he crafted two steel hero swords and worked on a few aluminum blades.

The Evolution of Swordsmithing

As the film industry has evolved, so has Peter’s craft. While he remains dedicated to traditional hand-forging techniques, he has also embraced modern advancements such as 3D printing and CNC machining to enhance precision and efficiency. His ability to balance time-honored craftsmanship with innovative technology has kept him at the forefront of the industry.

Legacy and Influence

Beyond film, Peter Lyon’s work has inspired a new generation of swordsmiths and enthusiasts. His designs have been immortalized in high-quality replicas through The Master Swordsmith’s Collection, allowing fans to own a piece of movie history. His impact on the world of fantasy weaponry is unparalleled, and his legacy continues to shape the future of cinematic craftsmanship.

Interview with Peter Lyon

Could you share the journey that led you from being a self-taught swordsmith in Shannon, New Zealand, to crafting iconic weapons for major film franchises like “The Lord of the Rings” and “The Hobbit”?

I got into medieval re-enactment at university in Palmerston North, but couldn’t get much equipment (no internet in the 80s!), so when I moved to Wellington I started making equipment and building up a workshop.

People started asking me to make swords & armor, the money from that funded more equipment, and in 1994 I decided to work at it full time.

The next few years were a struggle, but I built the skills and met Richard Taylor

1

while he was working on the Hercules TV series;

2

in 1998 he called me to work on LOTR.

Reflecting on your extensive career, which sword or weapon stands out as the most challenging to create, and what specific obstacles did you encounter during its production?

Not a sword, but Sauron’s mace. The hero mace was metal but would be impossibly heavy, so it was aluminum, so it was a learning curve. Complex components, etching all over it, but very satisfying to make. The head had 6 flanges, so I had to make the core, TIG weld on the flanges and smooth the welds to blend the shape, then sort out the etch with templates and liquid mask. Then the biggest acid bath I have ever done because it was so tricky. The other parts were similarly complex. All up, it was about 200 hours of work, and it is still on display at Wētā.

The design of Andúril is both intricate and symbolic. Can you delve into the collaborative process with John Howe and the techniques you employed to bring this legendary sword to life?

Most of the design work was done before I saw the design, but my contributions there were suggesting it be a 2-handed sword just to be impressive, and make the etches in the blade large enough to read—the designers were showing small etches that would be hard to read. I think Ben Wootten 4 did the design on Narsil/Andúril 5 . I liked that it was unique in its details yet a classic medieval-type of cruciform sword.

In “The Hobbit: An Unexpected Journey”, Orcrist 6 features a unique single-edged blade. What inspired this design choice, and how did it influence your approach to its craftsmanship?

The designer (not me) drew on the shape of Sting and modified that as a starting point.

The large-scale (actor scale) version was hard work, big & heavy, so I did the blade grinding in bursts of work. As I was shaping the handguard, I saw it as being the shape of a raptor’s claw, so I followed that mental image.

Your work on “Mulan” involved creating over 4,000 weapons and 300 suits of armor. How did you balance the need for historical authenticity with the practical demands of film production?

Well, I didn’t make all those weapons and armor, Wētā did! My role was to lead the work on the hero sword,

7

and work on some oversized parts and aluminum swords. It is essential to understand that no one person does all the work on any single item on a production like this, it is all a large and complex team effort.

On Mulan’s sword, the design was set, but within those constraints, I worked to make the sword as practical and maintainable as possible, so for example, the blade thins towards the tip to still be stiff but as light as possible. Also, the hilt is held together with two bamboo shims, which allow it to be dismantled if maintenance is needed—it was a mirror-finish blade.

The transition from traditional hand-forging to incorporating modern technologies is evident in your creations. How have advancements like 3D printing and CNC machining impacted your swordsmithing techniques?

A lot. As well as allowing the workloads to be spread around different departments to avoid choke points, these technologies let us do things that would otherwise be uneconomical or even impossible.

3D printing—usually plastics for hilt masters, but complex metal parts can also be printed, and it is getting less expensive as the tech is more available and advanced..

CNC—a good example is the dwarf swords in The Hobbit. Precision cutting of geometric blade details that would otherwise be impractically expensive or just impossible to get accurate..

Laser engraving of metals—allows super precise cutting of designs that would be risky or nearly impossible using templates and acids.

Wētā Workshop is renowned for its collaborative environment. Could you share an instance where teamwork within the workshop led to a particularly innovative solution or design?

I can’t think of a particular instance offhand, but collaboration can ensure the build proceeds smoothly through the multiple departments and skill sets needed on any item.

Fans often marvel at the realism of the weapons in films. How do you ensure that the swords not only look authentic on screen but also meet the safety and functional requirements for actors during filming?

The authenticity comes from trying to make each sword design as a real sword, within the constraints of the design itself—constructed and finished to ‘look right.’ But safety on set is imperative as each prop is handled by multiple people, so very few swords are made sharp unless there is a specific need.

The steel swords are made to be the best weight and balance the design allows, but steel swords are kept for hero shots only. Fights are done with stunt versions (aluminum blades with urethane hilts)

8 that are less than half the weight, and background props are often painted urethane for mass production at reasonable costs.

Your creations have become iconic in popular culture. How does it feel to see your work inspire merchandise, collectibles, and even influence real-world swordsmithing enthusiasts?

It feels great, but still a little unreal even after all these years. LOTR in particular—I knew it was going to be big, but I didn’t realize how it would become a cultural icon that has endured all these years.

Just as I was influenced by the swords of Conan the Barbarian,

9

other makers have been influenced by my work on LOTR and inspired by it—and that is awesome!

Even now, after 24 years, I am able to revisit the LOTR designs for the Master Swordsmith Collection. The only difference is using the extra skills I and my team have built to refine them even further.

The Master Swordsmith’s Collection 10 offers fans high-quality replicas of film swords. What considerations go into adapting a screen-used prop into a collectible item for the public?

Ironically, an exact replica built to the standards I could achieve 25 years ago wouldn’t stand muster to collectors today—the grind are a little imperfect and the symmetry was not always perfect; and where the originals were made as one-offs, we approach the collectibles as production-line pieces; this means waterjet-cut 11 blades so each is identical, 3D modeling, bronze parts where the originals were hand-sculpted, and things like that so each collectible should look like another.

With the evolving landscape of film production and the increasing use of digital effects, how do you foresee the role of traditional prop-making, particularly swordsmithing, changing in the industry?

There is definitely less demand for steel swords, partly because they are so time-consuming and expensive; instead, there are more ‘hero’ quality aluminum weapons.

There will always be a need for hand-props, as even with CGI, it is still common to composite real actors and props into scenes.

For aspiring swordsmiths and prop makers, what advice would you offer regarding the skills and mindset necessary to succeed in the intersection of traditional craftsmanship and modern filmmaking?

The path into the film industry has always been hard, and especially so for traditional crafts. I am fortunate that it has become my living, but for most people, film work is one contract at a time. So don’t rely on the film industry alone—keep your own workshop going in the between times.

You may have to accept compromises—parts of your craft might have to be altered to fit the needs and schedules of a film shoot; likewise, you might be asked to apply your skills in unexpected ways. Put everything into the pieces you make, but at the end of the job, step away and accept that your work may not appear the way you expect it to, or even not at all.

Footnotes

- 1 Richard Taylor: Co-founder of Wētā Workshop and key designer of props and weapons for The Lord of the Rings and The Hobbit. [Back to Question]

- 2 Hercules TV Series: Refers to Hercules: The Legendary Journeys, a TV series that aired from 1995 to 1999, which served as an early proving ground for Wētā Workshop’s craftsmanship. [Back to Question]

- 3 TIG Welding: A precise welding technique used in metal fabrication and prop-making. [Back to Question]

- 4 Ben Wootten: Conceptual designer for Wētā Workshop who contributed to the look of Middle-earth’s weapons. [Back to Question]

- 5 Narsil/Andúril: The legendary sword of Elendil, reforged into Andúril for Aragorn. [Back to Question]

- 6 Orcrist: The sword of Thorin Oakenshield, distinct from traditional Elven weapons. [Back to Question]

- 7 Hero vs. Stunt Weapons: High-detail metal props vs. lightweight stunt weapons for safety. [Back to Question]

- 8 Urethane Props: Lightweight and durable material used for background weapons and armor. [Back to Question]

- 9 Conan the Barbarian: The 1982 film influenced modern fantasy weapon aesthetics. [Back to Question]

- 10 Master Swordsmith Collection: Wētā Workshop’s high-end film-accurate replica line. [Back to Question]

- 11 Waterjet Cutting: A high-precision technique used in crafting replica swords. [Back to Question]

Discover more from Tales From The Collection

Subscribe to get the latest posts sent to your email.